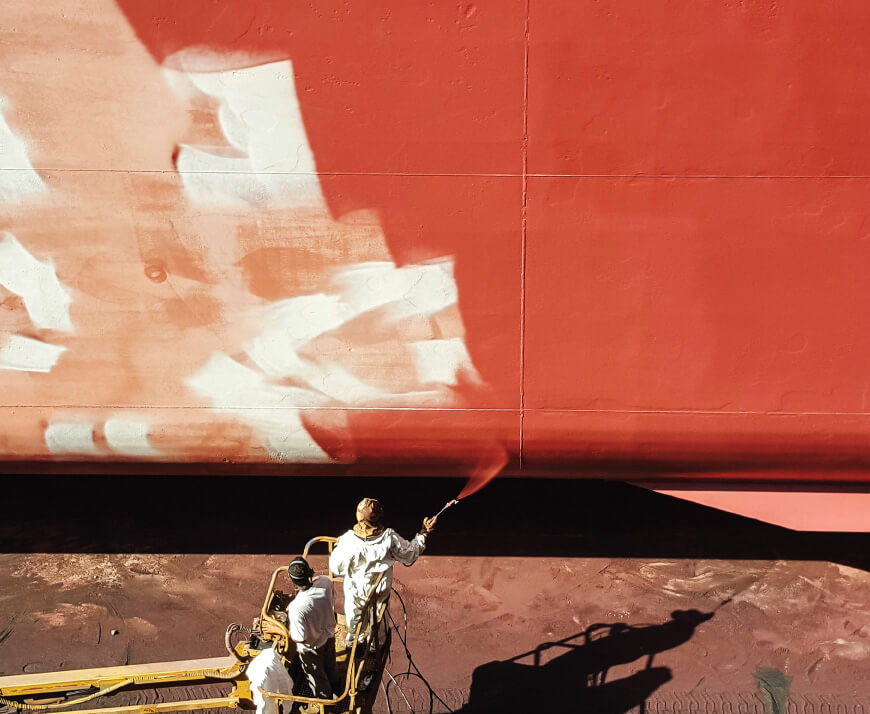

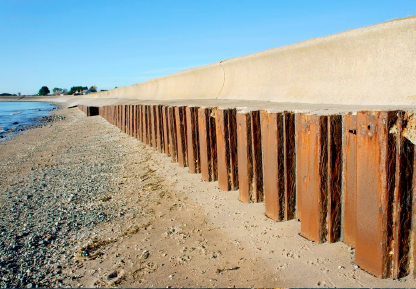

Our Marine Coatings help bring value to our clients by:

- Reducing Maintenance Intervals

- Reducing Dry Times, Recoat Windows, & Handling Times

- Reducing Labor Costs with One Coat Systems using Direct to Metal and High Build Products

- Simplifying Coating Specifications with Multifunctional Coatings

- Reducing Downtime

- Increasing the Life of their Assets

- Reducing and Eliminating VOCs & HAPs for a Positive Environmental Impact