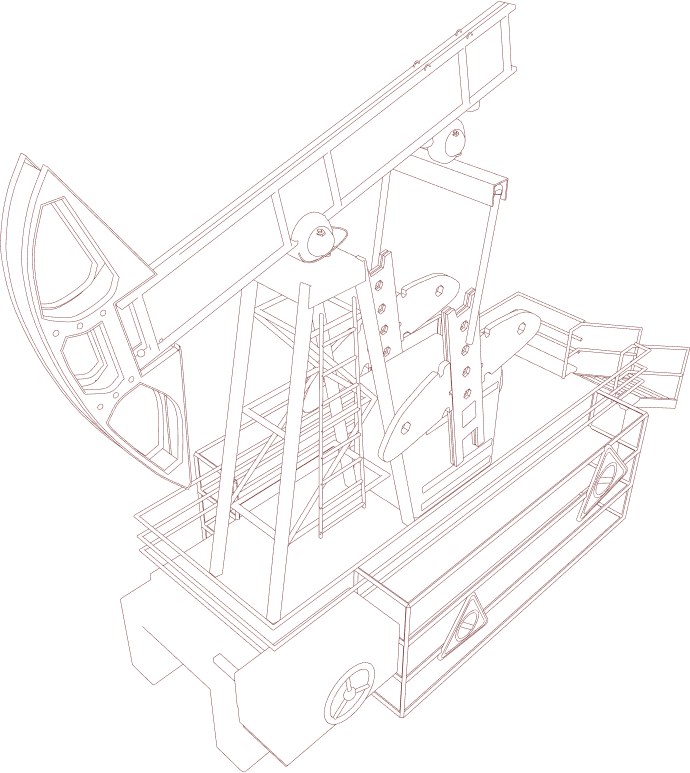

OILFIELD PRODUCTS

Riteks offers the perfect blend of standard and custom products for the specific demands of oilfield operations.

Riteks offers the perfect blend of standard and custom products for the specific demands of oilfield operations.

Start a conversation today and get a chemical solution designed to help you optimize efficiency and maximize performance.